As a form of vehicle connection, bonding is more and more used in the automotive design process due to its high reliability, unique structure, low cost, and other advantages.

The application of the bonding form effectively avoids drilling holes on the body, avoids the risk of body corrosion, and effectively reduces the rust prevention cost of the vehicle;

at the same time, it avoids welding, bolts, and other connection forms, effectively reducing processing steps and making the design of the vehicle flexible;

The important thing is to integrate the connection system and components to increase the cost of the entire vehicle and reduce the cost of the system.

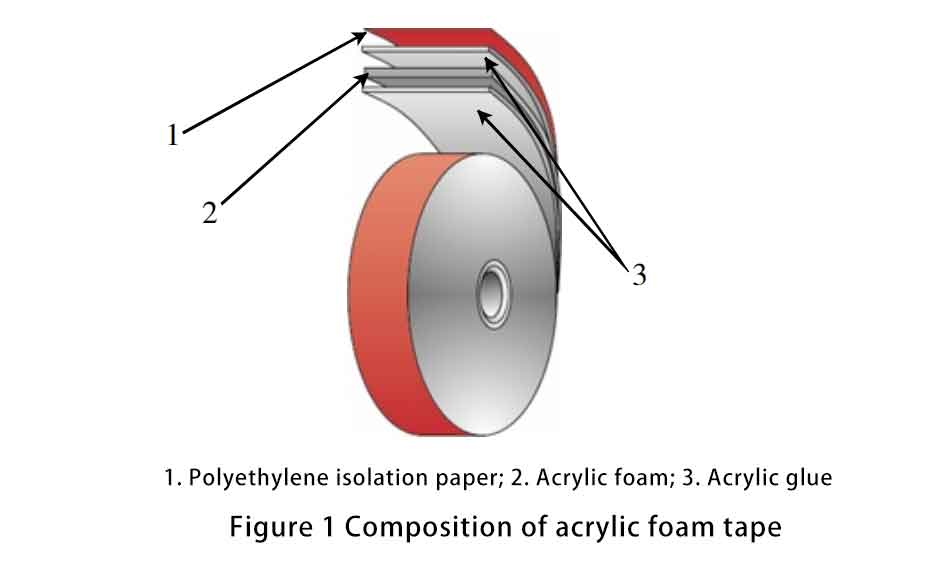

The composition of acrylic foam tape

Acrylic foam tape is mainly composed of acrylic glue, acrylic foam, and polyethylene release paper. As shown in Figure 1.

Connection form selection

Connection forms include bolts, glue, tape, screws, buckles, hinges, welding, etc. Bonding has the following advantages (Table 1) and is widely used in the design and production of the entire vehicle.

Table 1

| Advantage | Can avoid problems | Benefits |

| There is no need to open holes in the car body | Positioning between corrosion holes | Reduce rust prevention; Reduce the cost of opening holes |

| No welding and bolt connection | Welding tool maintenance | Reduce the flexible design of processing procedures |

| Integrating connection system and components | Complex lap relationship of parts gap surface difference between connectors | Improve vehicle quality and reduce system cost |

Instructions for Acrylic Foam Tape

(1) Surface treatment, use isopropanol, gasoline, or toluene to clean the oil and dust on the bonding surface;

(2) Apply the primer and use a clean tool to evenly apply the primer to the bonding surface;

(3) Dry, after the primer is dry, stick the tape; the recommended drying time is 30 seconds to 5 minutes at room temperature; when the operating temperature is lower than 16℃, it is recommended to use a heater; when the primer is covered for 24 hours, To avoid contamination of the surface, it needs to be cleaned again, and the picture is painted on the bottom;

(4) Adhesive tape positioning. On the surface where the primer is applied, the tape will be difficult to pull down and reposition; use a special tool to roll, the pressure must reach 2kgf/cm2 or 6.5kgf roller; the best operating temperature is 25℃~30℃, The recommended operating temperature is 16°C~43°C.

When the operating temperature is lower than 16°C, a heater is recommended; avoid external force immediately after pasting, as the bonding force will increase with time.

Quote-[1] Zhao Hailong. Application of acrylic foam tape in automobiles [J]. Modern Manufacturing Technology and Equipment, 2015,000(003): 51-53