With the development of China’s economy, the automobile industry has entered a stage of rapid development.

While designing new models, car designers constantly consider how to realize the structure of the car, especially how to realize that the fixed structure of the interior and exterior trim is more optimized, more economical, and more environmentally friendly than the existing fixed structure.

As a new generation of acrylic foam tape, designers have more choices in the fixing of automotive interior and exterior products.

Acrylic foam tape

The development of acrylic foam tape

Until the 1960s, automobile exterior parts were mainly fixed by mechanical means.

It was not until the 1960s that neoprene tape was gradually used to replace the mechanical fixing method to fix car exterior accessories such as nameplates and narrow trim strips.

However, with the development of the automobile industry, the performance of neoprene tape can no longer meet the higher requirements of exterior trim fixing.

In the early 1980 s, Acrylic foam tape gradually replaced neoprene tape and began to be applied to the fixation of automobile exterior accessories.

Nowadays, with the continuous development of the automobile paint system, the acrylic pressure-sensitive adhesive has been able to meet the requirements of ordinary paint systems, acid rain resistant paint systems, requirements for special paint systems such as scratch-resistant paint systems and high solid molecular paint systems.

Properties of Acrylic foam tape

Meeting the strict requirements of automobile use has become the key to whether Acrylic foam tape can truly replace the mechanical fixation method and optimize the body structure.

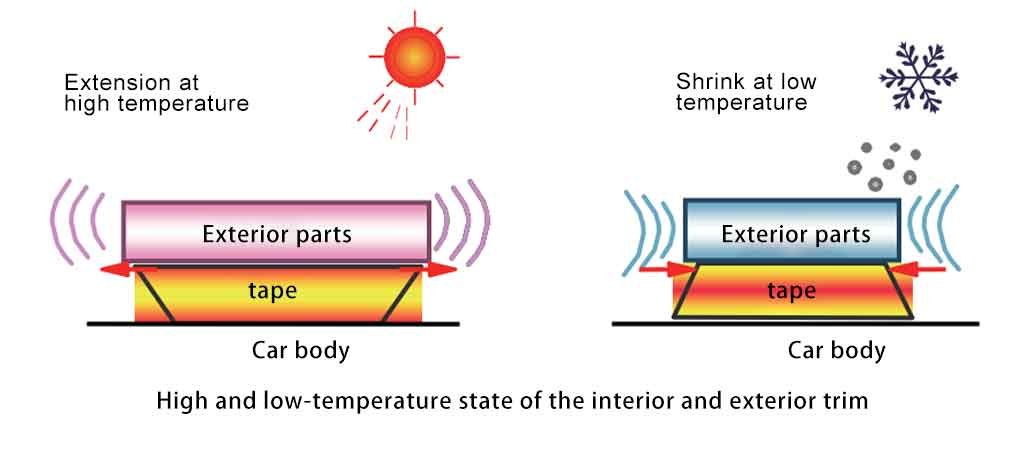

Thermal expansion and contraction of exterior parts

Let us first understand the application of interior and exterior trim parts. Figure 1 shows the different states of the parts under high and low-temperature conditions.

Quote-[1] Fang Xiaoyong. The application of acrylic foam tape in automobile structure optimization [J]. Automotive Engineers, 2011, 000 (002): 55-58