Acrylic foam tape bonding, as the name implies, is to use acrylic foam tape to connect the adhered parts together, and form a sandwich structure with the adhered parts.

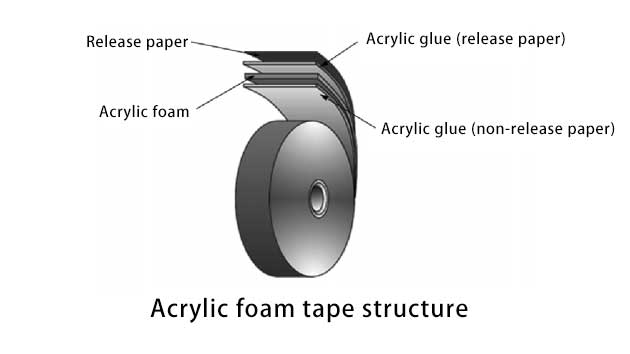

The structure of the acrylic foam tape is shown in Figure 1, where the acrylic foam core and the acrylic glue on both sides are the same. According to the principle of similar compatibility, compared with other common types of tape (polyester or polyurethane foam tape), acrylic foam tape Has excellent stress dispersion properties.

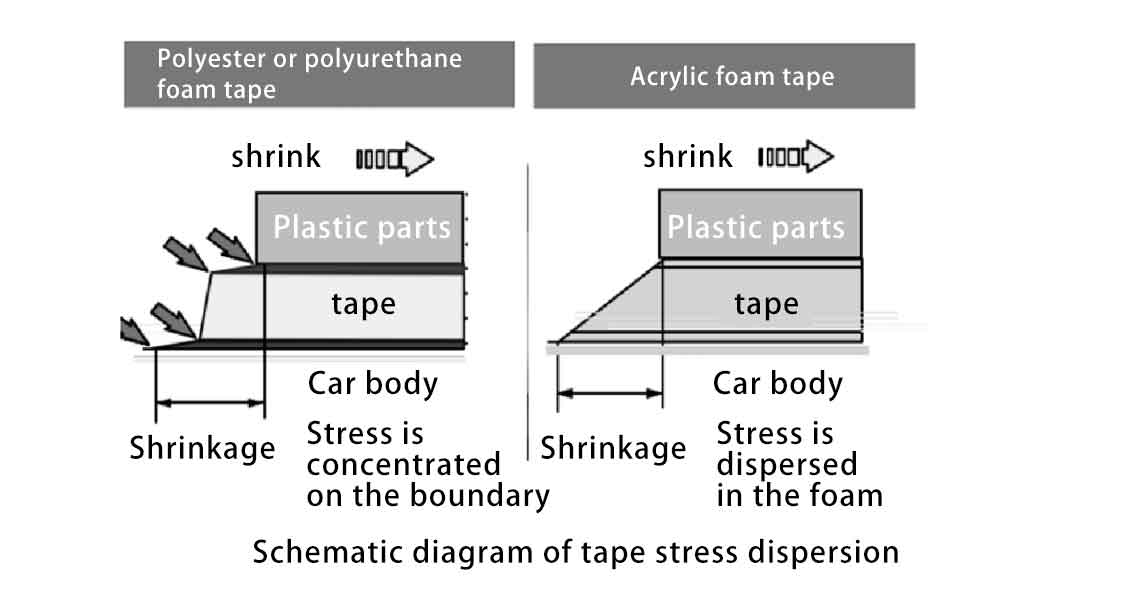

Under working conditions, the shrinkage rate of the parts on both sides of the tape is inconsistent or the force is inconsistent, resulting in a sheer effect between the two

The acrylic adhesive and the parts and the inner core (in Figure 2) of the ordinary type of tape have large stresses. The polyester or polyurethane foam core cannot disperse the stress well, so the tape is easy to separate from the adhered parts. Degumming phenomenon;

In the acrylic foam tape, the glue on both sides and the acrylic foam core can be seen as a whole, and the stress can be dispersed throughout the tape, which greatly reduces the risk of degumming.

Acrylic foam tape is widely used in automobile interior and exterior decorations, such as wheel eyebrows, under door guards, spoilers, word signs, sunroof sealing strips, door sealing strips, roof, and sunroof mushroom buckles, etc.

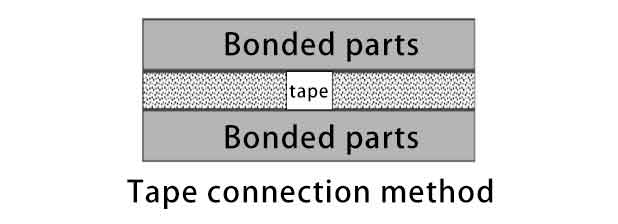

For the welding connection method, since there is no need to repeat disassembly and assembly, you can use the method shown in Figure 3 to connect and fix, and directly use the acrylic foam tape to bond the adhered parts together.

This can usually replace some commonly used welding processes, such as the welding between the defrost duct and duct reinforcement, the inner and outer panels of the glove box, etc. mentioned above.

Under normal circumstances, the welding strength of plastic parts is about 200N, and the positive pull strength of acrylic foam tape at room temperature is about 60-90N/cm² (foam tearing), so only about 4cm² of acrylic foam tape is needed.

It can meet its mechanical performance requirements, which is very easy to achieve when designing the adhesive surface of the tape.

Quotation-1] Senior. It’s all caused by the stickiness-the invention of the glue and tape family [J]. Invention and Innovation (in the middle school era), 2015,000(007): 11-12