Storage conditions of the tape

The room temperature is 20-22°C, and the humidity is 50% relative humidity. Place the roll of tape flat in the original package and avoid direct light sources (such as lights, sunlight), and place it at a distance of more than 20 cm from the ground.

Conditions of use of tape

In order to ensure good adhesion during the use of the tape, the surface of the wound object must be clean and dry to ensure that there is no grease, cloth scraps, dust, wax, organic solvents, etc., and there is no typical cleaning agent including esters (such as Acetone), ketones (such as MEK) and products based on NAPTHA.

Tape winding method in practical application

The dense winding of tape in wire harness

In dense winding, 1/2 and 1/4 laminated winding are generally used.

After a dense winding, the tape on the wire is two layers and one layer respectively, so that the tape can play a good role in sealing and insulating the wiring harness so that The wires inside the wire harness are not easily damaged by the outside world, as shown in Figure 1.

This winding method is generally used in wiring harnesses in the engine compartment.

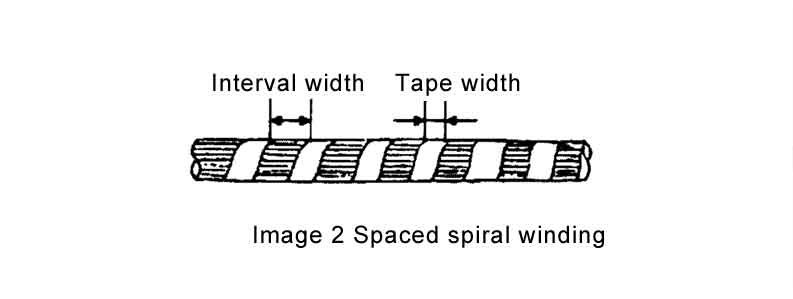

Interval non-helical winding

When the tape is being wound. The winding method is the same as close winding.

The difference with close winding is that the wires are evenly exposed after winding.

Generally, the spacing distance is 0.5-2.0 tape widths of the actual tape width. As shown in Figure 2, this winding method is general. Used in the indoor wiring harness.

Interval non-helical winding

The tape is not spirally wound when it is wound. After winding, the bare wires are exposed and the winding is uneven.

In general, the interval distance after the tape is wound is 80 to 200 ram. As shown in Figure 3, this winding method is generally used on the protective sleeve bellows outside the wire harness.